Safety isn’t a word, it’s an action plan.

Before you drop a tree, you need a plan. The Five Step Felling Plan can save your life.

The first step of the Felling Plan is called heights, hazards, and lean. You cannot drop a tree safely with out determining the height, assessing the tree and area for hazards, and measuring lean.

How tall is the tree?

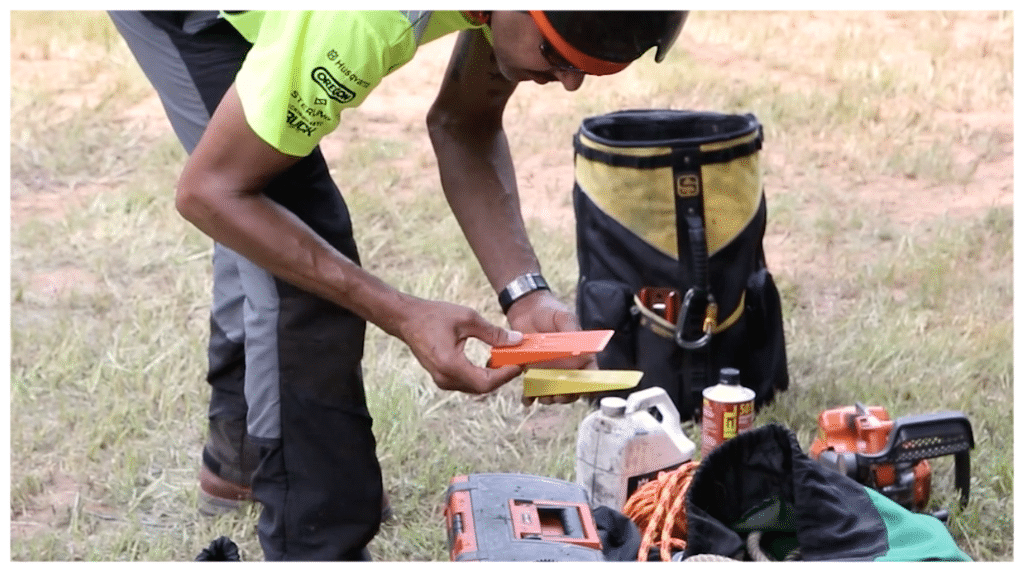

There are many ways to determine the height of a tree. There are cell phone apps that can help you, and tools such as a clinometer or transit. The technique demonstrated here relies on free equipment almost always available at your work site: a stick!

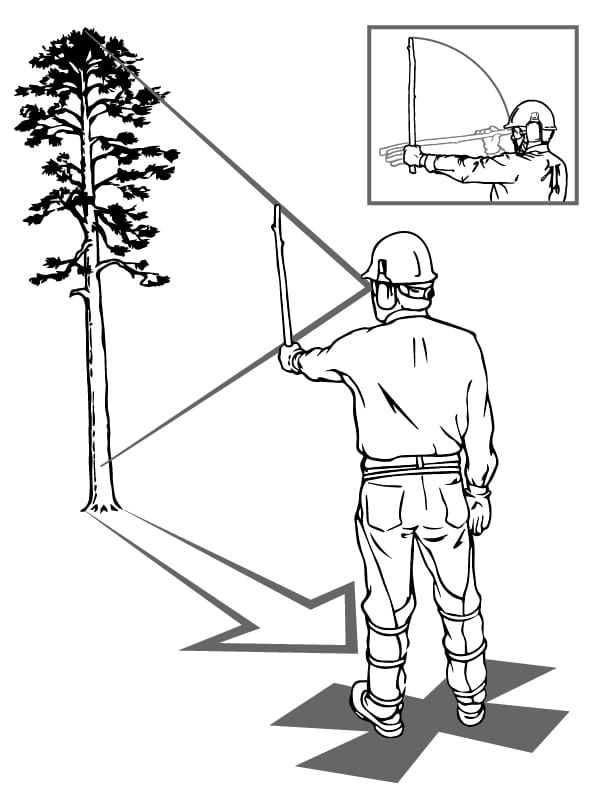

The stick trick for measuring tree height is easy and fairly accurate. You need to find a stick as long as the distance between your hand, when your arm is outstretched, and your eye. (Measure with your safety glasses on! Don’t poke out your eye!) Break off the stick or just hold it in your hand at that length.

- Line your hand up with the spot on the tree where you will cut the notch.

- Rotate the stick 90 degrees without moving your head or dropping your arm.

- Then walk backwards, away from the tree, until the tip of the stick is even with the top of the tree.

- It is important to hold your hand and arm still and to move your eyes, and not your head when you are lining up the tree.

When the tip of the stick lines up with the tip of the tree, you should be standing where the tip of the tree will fall.

The height estimate must be adjusted for front and back lean and topography. If the tree leans forward the height will be over estimated and if it has back lean, this method will underestimate the height. Similarly if the tree is on a slope falling up hill the height estimate will be low and if it is falling downhill the height will be overestimated.

What are the hazards?

Next, it is time to look for hazards. Take a walk around the tree and look at it very carefully. There are many potential hazards. Anything the tree may hit on the way down is also a hazard. Buildings, fountains, electrical wires, people, wildlife, and cars are just a few of the hazards that must be avoided.

Next, it is time to look for hazards. Take a walk around the tree and look at it very carefully. There are many potential hazards. Anything the tree may hit on the way down is also a hazard. Buildings, fountains, electrical wires, people, wildlife, and cars are just a few of the hazards that must be avoided.

Another tree which can change the direction of the fall or hangup the tree you want to fell is a potential hazard.

Some sites are loaded with hazards!

We talked about hazards found on the tree itself in the previous newsletter, but I have to remind you to take a good look at the tree as well.

Does the tree lean?

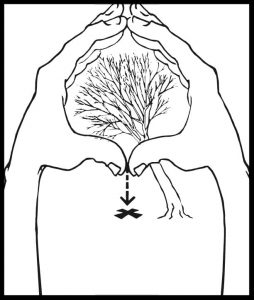

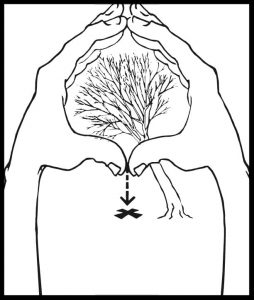

There is an easy way to tell if a tree has lean. Make a circle by placing your index fingers and thumbs together. Peer through the circle and step back until you have most of the tree’s canopy in the circle. Drop an imaginary line from your index fingers and thumbs to the ground. How far is that line from the base of the tree? In this case it is 4 feet.

There is an easy way to tell if a tree has lean. Make a circle by placing your index fingers and thumbs together. Peer through the circle and step back until you have most of the tree’s canopy in the circle. Drop an imaginary line from your index fingers and thumbs to the ground. How far is that line from the base of the tree? In this case it is 4 feet.

Lean needs to be measured at two separate locations. First measure lean in the line along which you intend to drop the tree. Then, move 90 degrees perpendicular to that and measure lean.

Generally if the tree has 3 feet or less of side lean, the notch may be adjusted to compensate. If it has more than 3 feet of side lean the tree will not fall in its intended path and you must come up with a new plan.

If you decide to adjust the line in which the tree will be felled, re-assess the lean again in the new line of fall and again, 90 degrees perpendicular to it.

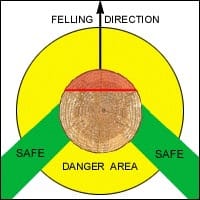

When you finish this first step, you should have identified an intended path of fall.

We usually end with a video, but there are so many on YouTube in which cutters failed to assess Height, Hazards, and Lean that it is pointless to select one here.